"Spanfeller is a twat" (theaspiringengineer)

"Spanfeller is a twat" (theaspiringengineer)

03/02/2018 at 10:44 ē Filed to: IS IT A SHITPOST IF IT'S CAR RELATED.

1

1

30

30

"Spanfeller is a twat" (theaspiringengineer)

"Spanfeller is a twat" (theaspiringengineer)

03/02/2018 at 10:44 ē Filed to: IS IT A SHITPOST IF IT'S CAR RELATED. |  1 1

|  30 30 |

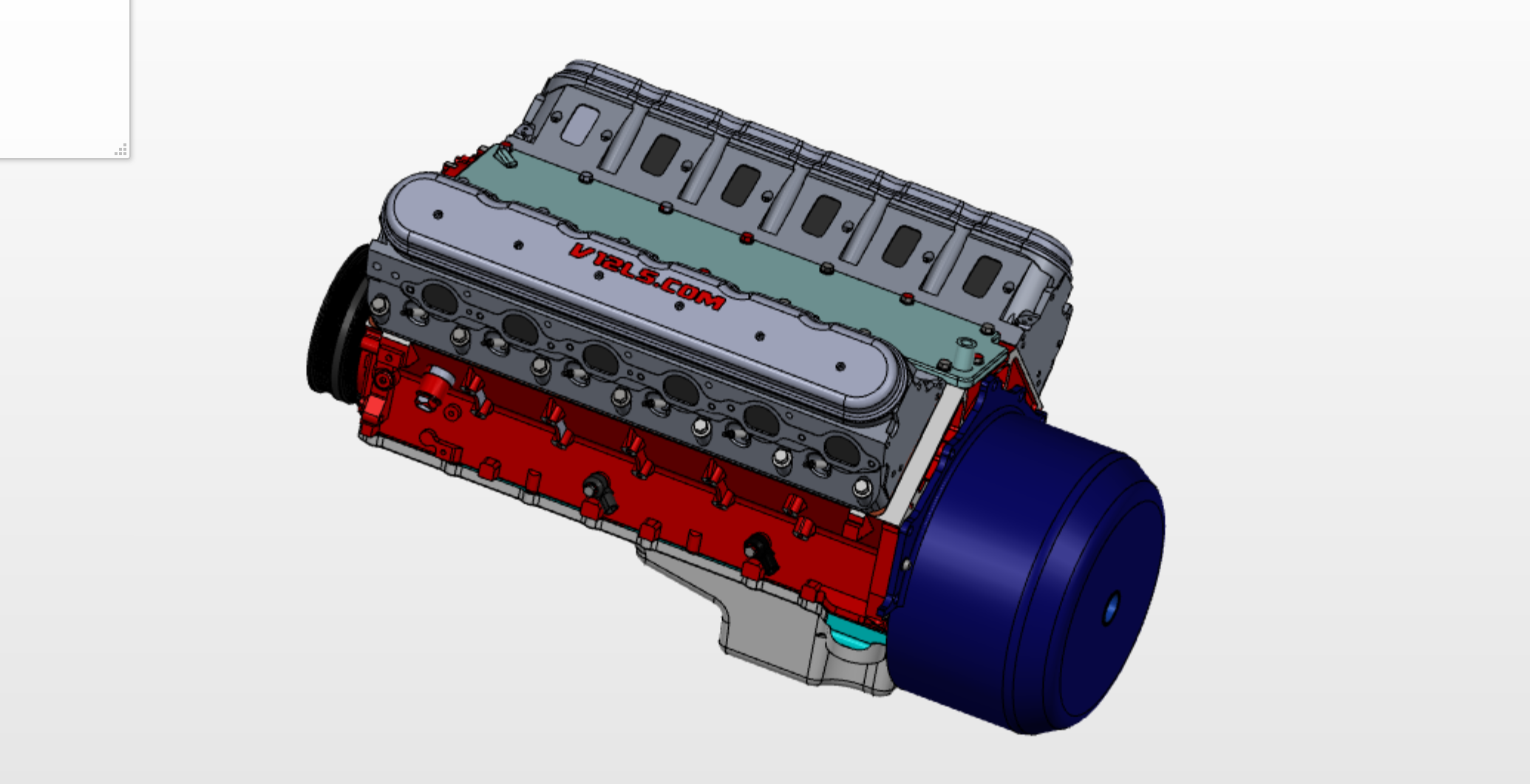

Yes, youíre looking at a CAD model of an LS engine if it had four more cylinders. Its a push-rod v12.

Did I make it? no. I was looking for a CAD file of an LS block for a project some colleagues and I are undertaking when I stumbled upon this gloriously crazy thing. If the designer made it using an LT1 as basis; it would be of around 9.3L in displacement, Madness!

I canít even.

In case you wonder, weíre making a cylinder head for an LS motor. Possibly an LT1.

Nibby

> Spanfeller is a twat

Nibby

> Spanfeller is a twat

03/02/2018 at 10:44 |

|

now make one with 48 cylinders pls

Spanfeller is a twat

> Nibby

Spanfeller is a twat

> Nibby

03/02/2018 at 10:46 |

|

37.2 L?

Cheaters would round that up to 40.

crowmolly

> Spanfeller is a twat

crowmolly

> Spanfeller is a twat

03/02/2018 at 10:51 |

|

Exists.

Spanfeller is a twat

> crowmolly

Spanfeller is a twat

> crowmolly

03/02/2018 at 10:53 |

|

Thatís the sound of a sophisticated american

benjrblant

> Spanfeller is a twat

benjrblant

> Spanfeller is a twat

03/02/2018 at 10:54 |

|

Thatís more exciting than what Iím working on!

I was speaking with a friend a few months ago about a hypothetical car company, we agreed that the engine offerings would be 0.5l/cyl and be offered in a 4cyl, i6, flat 12, or w24, because why not?

Spanfeller is a twat

> benjrblant

Spanfeller is a twat

> benjrblant

03/02/2018 at 10:56 |

|

Because friction losses and maintenance expenses!

Spanfeller is a twat

> benjrblant

Spanfeller is a twat

> benjrblant

03/02/2018 at 10:56 |

|

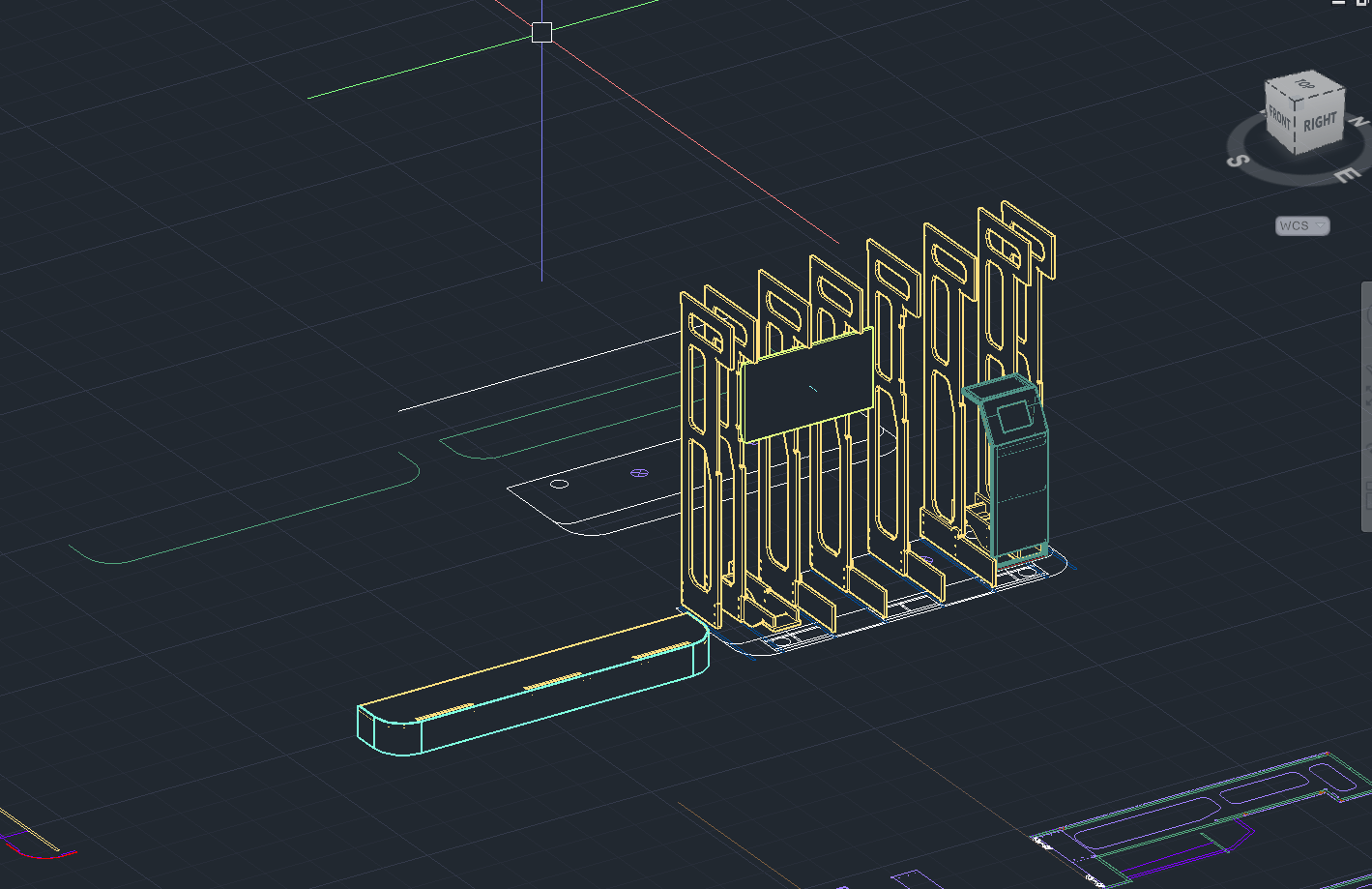

what is it that youíre drawing?

benjrblant

> Spanfeller is a twat

benjrblant

> Spanfeller is a twat

03/02/2018 at 11:03 |

|

But think how smooth a 6.0L flat-12 would sound. And so smooth! Mmm... Itís a kiosk for a client, portable, ipads and a tv on it. This is the CNC model.

HammerheadFistpunch

> Spanfeller is a twat

HammerheadFistpunch

> Spanfeller is a twat

03/02/2018 at 11:07 |

|

you can buy it

Spanfeller is a twat

> benjrblant

Spanfeller is a twat

> benjrblant

03/02/2018 at 11:09 |

|

Must have a big ass CNC machine at your disposal for those dimensions.

It would be smooth as hell. However, if you want to make an f12 you might need a very wide car if you want to mount it at the front.... or very short connecting rods, pick your poison, both have unintended consequences....

Smallbear wants a modern Syclone, local Maple Leafs spammer

> Spanfeller is a twat

Smallbear wants a modern Syclone, local Maple Leafs spammer

> Spanfeller is a twat

03/02/2018 at 11:11 |

|

Future next gen S2000 owner

> benjrblant

Future next gen S2000 owner

> benjrblant

03/02/2018 at 11:21 |

|

Why are you doing that in AutoCAD.

benjrblant

> Spanfeller is a twat

benjrblant

> Spanfeller is a twat

03/02/2018 at 11:22 |

|

Aye, we have some bigass CNC.

punkgoose17

> benjrblant

punkgoose17

> benjrblant

03/02/2018 at 11:23 |

|

The engine offerings for my car company would be a 90 degree V twin and possibly a 90 degree V4. The other possibilities are a 2 stroke I3 or a 2 stroke flat 4.

benjrblant

> Future next gen S2000 owner

benjrblant

> Future next gen S2000 owner

03/02/2018 at 11:23 |

|

Itís the companyís standard modeling software. Theyíve already got a lot of tools built for ACAD. Iíd rather be using fusion360 for this application.

Spanfeller is a twat

> punkgoose17

Spanfeller is a twat

> punkgoose17

03/02/2018 at 11:30 |

|

Iím still trying to figure out how to seal oval pistons for a straight six.

Spanfeller is a twat

> benjrblant

Spanfeller is a twat

> benjrblant

03/02/2018 at 11:31 |

|

Lovely

benjrblant

> Spanfeller is a twat

benjrblant

> Spanfeller is a twat

03/02/2018 at 12:15 |

|

Good luck with sealing oval pistons. I donít even know where to start with that.

punkgoose17

> Spanfeller is a twat

punkgoose17

> Spanfeller is a twat

03/02/2018 at 12:16 |

|

I am guessing the piston rings will have to be thicker at the narrow ends, and the rings would need a different inside curve profile than outside curve profile?

Spanfeller is a twat

> benjrblant

Spanfeller is a twat

> benjrblant

03/02/2018 at 12:50 |

|

Gas porting is one of the first steps to insure good expansion

Spanfeller is a twat

> punkgoose17

Spanfeller is a twat

> punkgoose17

03/02/2018 at 12:50 |

|

Yes, itís impossible. We donít even know where to start

Duck Duck Grey Duck FTMFW!

> Spanfeller is a twat

Duck Duck Grey Duck FTMFW!

> Spanfeller is a twat

03/02/2018 at 13:02 |

|

Shh!

punkgoose17

> Spanfeller is a twat

punkgoose17

> Spanfeller is a twat

03/02/2018 at 13:16 |

|

Have you tried: Model your cylinders and pistons at maximum temperature and minimum temperature. Then model the piston ring starting with the outside then model the inside so it meets the profile when shrunk to the minimum temperature. (I am not positive this will work, but this is where I would start. I want to do this, but I need to get back to my job.) Also you want elliptical pistons like the NR750 not oval like the NR500 for more uniform ring pressure on the cylinder walls.

DipodomysDeserti

> Spanfeller is a twat

DipodomysDeserti

> Spanfeller is a twat

03/02/2018 at 13:23 |

|

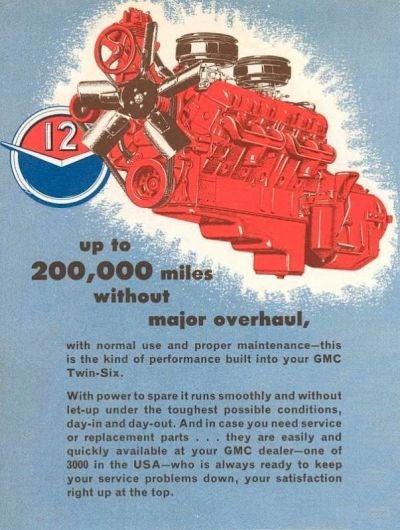

GMC made a factory pushrod V12 back in the Ď60s.

The crankshaft alone weighed 180 lbs.

Spanfeller is a twat

> punkgoose17

Spanfeller is a twat

> punkgoose17

03/02/2018 at 13:25 |

|

Iím making elliptical pistons. I forgot the name for a moment!

But piston rings are made out of different materials, no?

We were thinking of using a material that likes expanding and contracting a lot, and gasporting the pistons.

Spanfeller is a twat

> DipodomysDeserti

Spanfeller is a twat

> DipodomysDeserti

03/02/2018 at 13:28 |

|

Do you even lift?....the pistons?

/Joke

punkgoose17

> Spanfeller is a twat

punkgoose17

> Spanfeller is a twat

03/02/2018 at 14:19 |

|

It sounds like you are going in the right direction!

Yes, piston and rings are usually different materials. I am not sure what material to use. I would do a thought experiment of lower vs. similar vs. higher thermal coefficients of expansion and see what the possible effects are. My book that may have the answer is at home... (Quick searching online is showing things like martensitic chromium steel, spring steel and various types of cast iron. Which have lower thermal coefficients of expansion than steel and aluminum.)

I would avoid gasporting the pistons unless you were specifically designing a race engine. It would increase manufacturing costs and make it more difficult to theoretically determine your ring seal. You probably want to make the project easier for yourself.

Spanfeller is a twat

> punkgoose17

Spanfeller is a twat

> punkgoose17

03/02/2018 at 15:18 |

|

I mean its one of the solutions... weíre mostly worried about the first ring keeping the charge inside (we could go Honda-style on the other two and the oil ring). Weíre gas porting because one of our solutions would be not to actually use a conventional seal that has a ďspring loadedĒ effect because in an elliptical piston the expansion that spring-like effect is not consistent around the cylinder. So instead we want to cut the ring in half and actually overlap them a bit, have the gas ports expand the rings when needed (compression, ignition and exhaust) and have the vacuum created in the chamber contract the seal during intake so that we have a bit less friction (minimal really).

Weíre using public domain tech for everything because our teachers are trying to teach us a lesson about having fresh ideas, and that elliptical piston is a very long term project. Right now weíre focusing on an LS head with a freevalve system.

The Snowman

> Spanfeller is a twat

The Snowman

> Spanfeller is a twat

03/02/2018 at 22:14 |

|

Too lazy to look through all the comments but v12ls.com

Spanfeller is a twat

> The Snowman

Spanfeller is a twat

> The Snowman

03/02/2018 at 22:24 |

|

Crowmolly must be a hipster

Comented v12ls.com before it was cool